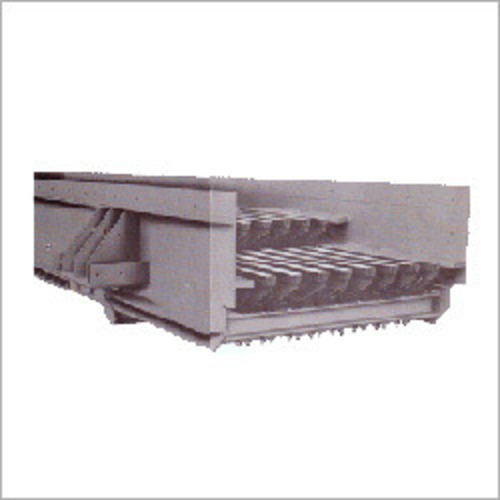

Grizzly Feeders

Product Details:

- Usage Industrial

- Condition New

- Power Source Electric

- Voltage 440 Volt (v)

- Attributes Strong Durable

- Click to view more

Grizzly Feeders Price And Quantity

- 450000.00 INR/Unit

- 1 Unit

Grizzly Feeders Product Specifications

- 440 Volt (v)

- Strong Durable

- Industrial

- New

- Electric

Grizzly Feeders Trade Information

- Mumbai, Mundra

- Cash Advance (CA) Cash in Advance (CID) Cheque Letter of Credit (L/C)

- 7-8 Months

- Customized Packing

- Australia North America Eastern Europe Africa Western Europe Middle East South America Asia Central America

- All India

- ISO

Product Description

Advanced technology and finest quality raw materials are used in the making of Grizzly Feeders. Robust in construction, these are utilized to adjust the consumption of the cone/ jaw crusher, which enables hassle-free operation of the crusher with high rate of production.

Basic Data you will require

The type of material being fed, the angle of repose and weight per cubic foot (kg/ m.cu). A rough calculation of the material sizes. The greatest dimension of the biggest piece. Needed feeder conveying distance. Ideal feeder capacity.

STEP 1: With the help of computed precision of big size materials, ideal width of the feeder is selected from Table A. Multiply this factor by the greatest dimension of the material's largest piece to determine minimal width of feeder width. There is also a throat opening factors where the use of a four-sided hopper is done. To find the minimal hopper throat opening proper factors are selected and multiplied by the same largest dimension.

STEP 2: Determine the different combinations of feeder slopes and widths available for the needed capacity. Neglect any which are tinier in width than the minimum feeder width calculated before. It may become necessary to enhance the minimum width of the feeder in order to gain the desired capacity. If so, ignore minimum width from previous step and substitute with the altered minimum feeder width for the needed capacity.

STEP 3: Now regard feeder length. Generally the positioning and size of companion equipment like conveyors, crushers, hoppers, aprons, chutes, etc. propose the given to minimized length of the feeder pan. Also, the pan could not be shorter than that which is required to hold the material at its repose angle on the pan after the shutting down of the feeder. Find out minimum pan lengthen make your own scaled diagram to demonstrate the angle of repose and slope of feeder on the rest and pan. Enable the throat opening of the proper hopper when utilizing a hopper with four sides. Add 12" (30 cm) to the length of the pan as a factor of safety to forestall the material from continuing to freely flowing. After this, add the length of any grizzly sections which is needed to the minimum pan length to ascertain the minimum feeder length.

STEP 4: Again evaluate slopes, width and capacities. Regard headroom and feeder length needs. Match these with location, critical dimensions and elevations of associated equipment. Recollect to allow for future demand of increase in capacity. Now select the slope/ width combination which matches the desired capacity and which is ideal for the particular installation and application. You would need to go steeper and narrower to match up with a crusher opening; possibly wider to have feed from an active apron conveyor. Or, you may need to go wider with comparatively less slopes to suit the limits of elevation. You are possibly to discover that although over one size feeder will fulfill your capacity needs, one specific width/ length/ slope combination optimally serves your predefined needs.

- The straight-line motion by VGF Series and grizzly feeders are for regulated feeding of primary crushers after screening.

- VGC Series Primary vibrating feeders mix run-of-quarry scalping and feeding oversize retained by grizzly bars to crusher. Fines passing the bars of steel spacing such as crusher jaw setting, could be directly sent to screening.

Advantages of Grizzly Feeder:

- Max. capacity working of the Crusher with low depreciation since the chamber for crushing is not filled with materials of undersize.

- Grizzly fines, released by belt conveyor, crushed prod, safeguard the rubber belt from shearing and attrition owing to the discharge of product from primary crusher.

Table A-Section Factors

|

Percentage Large Size* |

Feeder with Factor |

Hopper throat Factor |

|

1-10% |

1.3 |

1.5 |

|

10-40% |

1.5 |

2 |

|

40-60% |

2 |

2.5 |

|

60-90% |

2.5 |

3 |

|

90-100% |

3 |

3.5 |

Those pieces which have a size range of 75 to 100% of the greatest piece. If the largest piece is 91cm (36") then "largesize" are all pieces 69 cm (27") and larger.

Capabilities founded on material weighing 1600 kg/m.cu. (100 Ib./ft.cu), 30 cm(12") material bed depth and 13 mm (1/2") stroke at the rate of 800 RPM.

|

Slope of Pan |

Feeder Width in mm/tons per House |

||||||||

|

800 |

900 |

1100 |

1200 |

1400 |

1500 |

1800 |

2000 |

2500 |

|

|

0 DEG |

275 |

350 |

400 |

475 |

525 |

600 |

725 |

850 |

1000 |

|

5 DEG |

375 |

450 |

525 |

600 |

675 |

750 |

900 |

1050 |

1160 |

|

10 DEG |

450 |

550 |

650 |

725 |

825 |

900 |

1075 |

1250 |

1440 |

|

15DEG |

550 |

650 |

750 |

850 |

975 |

1075 |

1300 |

1500 |

1850 |

Technical Specification

|

Size |

VGF 800 |

VGF 900 |

VGF 1100 |

VGF 1200 |

VGF 1400 |

VGF 1500 |

VGF 1800 |

VGF 2000 |

VGF 2500 |

|

Size of |

800 |

900 |

1100 |

1200 |

1400 |

1500 |

1800 |

2000 |

2500 |

|

feed |

|

|

|

|

|

|

|

|

|

|

deck |

|

|

|

|

|

|

|

|

|

|

width |

|

|

|

|

|

|

|

|

|

|

Grizzly |

1600 |

1700 |

1800 |

2000 |

2400 |

2500 |

2600 |

3000 |

3200 |

|

length |

|

|

|

|

|

|

|

|

|

|

Total |

2800 |

3000 |

3300 |

3600 |

4200 |

4400 |

4600 |

5600 |

6600 |

|

length |

|

|

|

|

|

|

|

|

|

|

Grizzly |

50/ |

50/ |

50/ |

507 |

507 |

507 |

507 |

507 |

507 |

|

bars- |

150 |

180 |

200 |

200 |

250 |

250 |

300 |

350 |

400 |

|

openings |

|

|

|

|

|

|

|

|

|

|

Max. feed |

500 |

600 |

700 |

800 |

1000 |

1100 |

1200 |

1400 |

1600 |

|

size mm |

|

|

|

|

|

|

|

|

|

|

Max. |

250 |

350 |

400 |

480 |

640 |

750 |

1040 |

1200 |

1400 |

|

capacity |

|

|

|

|

|

|

|

|

|

|

TPH |

|

|

|

|

|

|

|

|

|

|

Horse |

15 |

20 |

25 |

30 |

30 |

40 |

50 |

75 |

100 |

|

power |

|

|

|

|

|

|

|

|

|

|

Wt. |

3500 |

4200 |

5200 |

6500 |

8800 |

9800 |

12200 |

14600 |

16200 |

|

Kgs. |

|

|

|

|

|

|

|

|

|

Features of Grizzly Feeder:

- Large welded frame to tolerate high shock loads.

- Transportation deck with grizzly and pan combination, back and side renewable liners.

- Stepped grizzly and non-plugging, singly renewable, for easy fines passing and material tilting.

- Vibrating unit comprises two counter-rotating eccentric shafts, geared jointly in oil-bath. Special roller bearings protected by grease labyrinths and in oil-bath.

- Varying imbalance of the machine effects the setting of amplitude.

- Actuation is by V-belts drive and 4-pole motor.

- Special steel springs ordered for the installation on steel supporting structure or concrete.

- Welded plate supporting structure (supplied on request), steel-sections preset and cross-breams for fines and feed discharge hopper application. It is possible to insert a device for uninterrupted output setting.

|

Mode |

A |

B |

C |

D |

E |

F |

G |

|

VGF 800 |

2800 |

800 |

1950 |

535 |

730 |

1290 |

1180 |

|

VGF 900 |

3000 |

900 |

2200 |

560 |

780 |

1350 |

1300 |

|

VGF 1000 |

3300 |

1100 |

2400 |

590 |

800 |

1400 |

1450 |

|

VGF 1200 |

3600 |

1200 |

2510 |

590 |

875 |

1460 |

1620 |

|

VGF 1400 |

4200 |

1400 |

2935 |

675 |

1000 |

1640 |

1800 |

|

VGF 1500 |

4400 |

1500 |

3100 |

700 |

1020 |

1720 |

2100 |

|

VGF 1800 |

4600 |

1800 |

3180 |

790 |

1190 |

1880 |

2275 |

|

VGF 2000 |

5600 |

2000 |

3500 |

900 |

1200 |

2000 |

2400 |

|

VGF 2500 |

6600 |

2500 |

4100 |

1100 |

1500 |

2200 |

2600 |

Grizzly Feeders are employed in a wide range of sectors and businesses, including mining, quarrying, construction, recycling, and bulk material handling. These industries have an urgent need for reliable solutions to properly manage resources and assure continuous operations. Grizzly Feeders are used by businesses and organizations to increase production, reduce downtime, and provide effective material separation and screening. These feeders, known for their dependability, enable a regular and uninterrupted flow of supplies. They prove to be vital assets by lowering maintenance expenses and downtime while increasing productivity and cost-effectiveness.

Grizzly Feeder FAQs

What is a grizzly feeder?

A grizzly feeder is a vibrating machine that removes fines and undersized particles from feed material before it enters the primary crusher or processing equipment.

What are the advantages of a grizzly feeder?

The feeder's efficiency and output have increased. Its use results in reduced maintenance needs and equipment protection

What materials may be treated with grizzly feeders?

Aggregates, minerals, ores, and many forms of industrial materials can all be handled using grizzly feeders.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese