Call Us Now :-08071932023

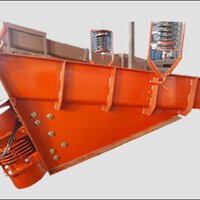

Industrial Feeder

500000.00 - 1500000.00 INR/Unit

Product Details:

- Width 600 - 2000 Millimeter (mm)

- Length 1500 - 3000 Millimeter (mm)

- Condition New

- Power Source Electric

- Warranty Standard

- Attributes Strong Durable

- Click to view more

X

Industrial Feeder Price And Quantity

- 500000.00 - 1500000.00 INR/Unit

- 1 Unit

Industrial Feeder Product Specifications

- 600 - 2000 Millimeter (mm)

- Electric

- 1500 - 3000 Millimeter (mm)

- New

- Strong Durable

- Standard

Industrial Feeder Trade Information

- Cash in Advance (CID) Cheque Cash Advance (CA) Letter of Credit (L/C)

- 7-8 Months

- Middle East South America Western Europe Asia North America Australia Central America Africa Eastern Europe

- All India

Product Description

An industrial feeder is a device used in manufacturing and industrial processes to efficiently and accurately feed materials or components into a production line or machine. These feeders are crucial for ensuring a continuous flow of materials at the required rate, which is essential for maintaining productivity and quality standards in various industries.

Industrial feeders come in various types and configurations, depending on the specific requirements of the application and the characteristics of the materials being handled.

Q. What is an industrial feeder

Ans: An industrial feeder is a device used in manufacturing and industrial processes to efficiently and accurately feed materials or components into a production line or machine.

Q. What types of materials can industrial feeders handle?

Ans: Industrial feeders can handle a wide range of materials, including powders, granules, pellets, liquids, parts, components, aggregates, and bulk solids.

Q. What are the common types of industrial feeders?

Ans: Common types of industrial feeders include vibratory feeders, screw feeders, belt feeders, apron feeders, and pneumatic feeders.

Q. What are the benefits of using industrial feeders?

Ans: The benefits of using industrial feeders include increased efficiency, improved accuracy, reduced labor costs, minimized material wastage, consistent material flow, and enhanced production quality.

Q. How do I select the right industrial feeder for my application?

Ans: The selection of an industrial feeder depends on factors such as the type and characteristics of the materials being handled, required feed rate, feeding distance, space constraints, and environmental conditions. Consulting with a reputable supplier or manufacturer is recommended to ensure the appropriate feeder is selected.

Q. How do industrial feeders work?

Ans: The operation of industrial feeders varies depending on the type. For example, vibratory feeders use vibration to move materials along a trough, while screw feeders use a rotating screw mechanism to transport materials along a chute or tube.

Q. Are industrial feeders customizable?

Ans: Yes, many industrial feeder manufacturers offer customization options to meet specific requirements, such as adjusting feed rates, modifying feeding mechanisms, incorporating special coatings for abrasive materials, and integrating control systems for automation.

Q. What maintenance is required for industrial feeders?

Ans: Maintenance requirements depend on the type of feeder and the operating conditions. Regular inspections, cleaning, lubrication, and replacement of worn parts are typical maintenance tasks to ensure optimal performance and longevity of industrial feeders.

Q. Can industrial feeders be integrated into existing production lines?

Ans: Yes, industrial feeders are designed to be easily integrated into existing production lines or machinery, often with minimal modifications required.

Q. Are industrial feeders suitable for hazardous environments

Ans: Some industrial feeders are specifically designed for use in hazardous environments, such as those with explosive atmospheres or extreme temperatures. It's essential to select feeders that comply with relevant safety standards and regulations for the specific environment.

Industrial feeders come in various types and configurations, depending on the specific requirements of the application and the characteristics of the materials being handled.

Some common types of industrial feeders include:

- Vibratory Feeders: These use vibration to move materials along a trough or tube. The vibration can be adjusted to control the flow rate and ensure even distribution of materials.

- Screw Feeders: Screw feeders use a rotating screw mechanism to move materials along a chute or tube. They are suitable for handling powders, granules, and other bulk materials.

- Belt Feeders: Belt feeders use a conveyor belt to transport materials from a storage hopper or bin to a processing machine. They are often used in mining, quarrying, and construction industries.

- Apron Feeders: Apron feeders consist of a series of overlapping metal plates or pans that are dragged along a conveyor chain. They are commonly used for handling heavy-duty materials such as coal, ore, and aggregates.

- Pneumatic Feeders: Pneumatic feeders use air pressure to transport materials through a system of pipes or tubes. They are suitable for handling materials that are sensitive to vibration or shear forces.

Industrial Feeder Applications:

- Automotive Manufacturing: Industrial feeders are used to supply parts and components to assembly lines, such as bolts, nuts, screws, and small metal parts.

- Food Processing: In the food industry, feeders are employed to handle ingredients such as grains, powders, spices, and additives, ensuring a consistent flow for mixing, blending, packaging, and other processes.

- Pharmaceuticals: Industrial feeders are crucial for accurately dispensing ingredients and materials used in pharmaceutical manufacturing, including powders, tablets, capsules, and liquids.

- Mining and Minerals: Feeders are utilized in mining operations to transport bulk materials like coal, ore, aggregates, and minerals from storage bins or hoppers to processing equipment such as crushers, screens, and conveyors.

- Chemical Processing: Industrial feeders play a role in the precise metering of chemicals and additives in chemical manufacturing processes, ensuring accurate blending, mixing, and reaction control.

- Construction Materials: Feeders are used in construction material manufacturing for handling aggregates, cement, sand, and other bulk materials, ensuring a continuous supply to production processes like concrete batching plants and asphalt mixing plants.

- Packaging: Industrial feeders are employed in packaging lines to feed products such as bottles, cans, cartons, and pouches onto conveyors for filling, labeling, sealing, and packaging operations.

- Plastics and Rubber: Feeders are used in the plastics and rubber industries to handle raw materials, additives, and compounds for extrusion, molding, and compounding processes.

- Textiles: Industrial feeders are utilized in textile manufacturing for feeding fibers, yarns, fabrics, and other materials to spinning, weaving, knitting, and dyeing machines.

- Electronics Manufacturing: In electronics manufacturing, feeders are used to supply electronic components such as chips, resistors, capacitors, and connectors to assembly lines for PCB assembly and surface mount technology (SMT) processes.

Industrial Feeder FAQ:

Q. What is an industrial feeder

Ans: An industrial feeder is a device used in manufacturing and industrial processes to efficiently and accurately feed materials or components into a production line or machine.

Q. What types of materials can industrial feeders handle?

Ans: Industrial feeders can handle a wide range of materials, including powders, granules, pellets, liquids, parts, components, aggregates, and bulk solids.

Q. What are the common types of industrial feeders?

Ans: Common types of industrial feeders include vibratory feeders, screw feeders, belt feeders, apron feeders, and pneumatic feeders.

Q. What are the benefits of using industrial feeders?

Ans: The benefits of using industrial feeders include increased efficiency, improved accuracy, reduced labor costs, minimized material wastage, consistent material flow, and enhanced production quality.

Q. How do I select the right industrial feeder for my application?

Ans: The selection of an industrial feeder depends on factors such as the type and characteristics of the materials being handled, required feed rate, feeding distance, space constraints, and environmental conditions. Consulting with a reputable supplier or manufacturer is recommended to ensure the appropriate feeder is selected.

Q. How do industrial feeders work?

Ans: The operation of industrial feeders varies depending on the type. For example, vibratory feeders use vibration to move materials along a trough, while screw feeders use a rotating screw mechanism to transport materials along a chute or tube.

Q. Are industrial feeders customizable?

Ans: Yes, many industrial feeder manufacturers offer customization options to meet specific requirements, such as adjusting feed rates, modifying feeding mechanisms, incorporating special coatings for abrasive materials, and integrating control systems for automation.

Q. What maintenance is required for industrial feeders?

Ans: Maintenance requirements depend on the type of feeder and the operating conditions. Regular inspections, cleaning, lubrication, and replacement of worn parts are typical maintenance tasks to ensure optimal performance and longevity of industrial feeders.

Q. Can industrial feeders be integrated into existing production lines?

Ans: Yes, industrial feeders are designed to be easily integrated into existing production lines or machinery, often with minimal modifications required.

Q. Are industrial feeders suitable for hazardous environments

Ans: Some industrial feeders are specifically designed for use in hazardous environments, such as those with explosive atmospheres or extreme temperatures. It's essential to select feeders that comply with relevant safety standards and regulations for the specific environment.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese