Call Us Now :-08071932023

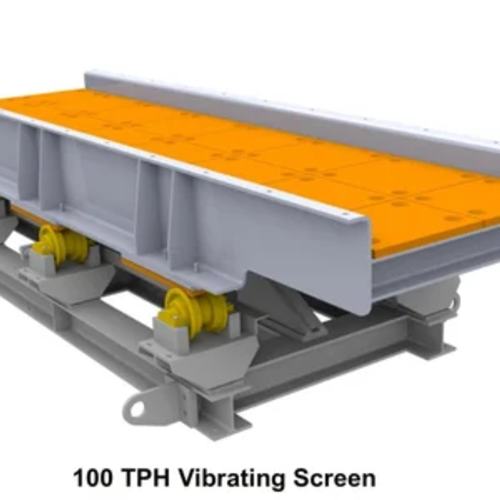

Multi Deck Vibrating Screen

1400000 INR/Unit

Product Details:

- Type Vibrating Screen

- Material Stainless Steel

- Processing Type Standard

- Condition New

- Power Mode Electric

- Voltage 380 Volt (v)

- Application Industrial

- Click to view more

X

Multi Deck Vibrating Screen Price And Quantity

- 1400000 INR/Unit

- 1 Unit

Multi Deck Vibrating Screen Product Specifications

- New

- Stainless Steel

- 380 Volt (v)

- Industrial

- Electric

- Vibrating Screen

- Standard

Multi Deck Vibrating Screen Trade Information

- Cash Advance (CA) Cash in Advance (CID) Cheque Letter of Credit (L/C)

- 7-8 Days

- Africa Middle East South America Asia North America Western Europe Eastern Europe Central America Australia

- All India

Product Description

Since our establishment in 1982, we have emerged as a prominent purveyor of state-of-the-art Multi Deck Vibrating Screens. This cutting-edge equipment has gained significant traction in sectors such as ceramics, food processing, chemicals, and other industries where it assumes a pivotal role in effectively segregating diverse materials. Our team of skilled specialists meticulously constructs this screen, employing premium-grade components and innovative methodologies, thereby ensuring exceptional performance and enduring reliability. The distinguishing hallmark of our Multi Deck Vibrating Screen lies in its robust and resilient structure, thoughtfully engineered to meet the escalating demands of contemporary enterprises. Crafted from heavy-duty mild steel, it effortlessly withstands formidable loads of up to 100 Kg, thereby guaranteeing unfaltering dependability and remarkable longevity.

Vibrating Screen Benefits

- With its usage, Screening of materials of various sizes in an efficient and precise manner is possibly done.

- It possesses Multiple decks increase screening capacity.

- The ability to change the tilt of the screen and the strength of the vibration.

- It has the capability to filter a broad variety of materials, ranging from tiny particles to coarse aggregates.

Vibrating Screen FAQs

What is a Multi Deck Vibrating Screen?

A Multi Deck Vibrating Screen is a screening machine that has numerous decks or levels placed one on top of the other. It uses vibration to separate and categorize materials of various sizes.

What is the working principle of a Multi Deck Vibrating Screen?

Multi Deck Vibrating Screens operate by vibrating the screens, forcing the materials to move and separate according to size. A motor with eccentric weights generates the vibration, which provides a circular or linear motion. Smaller particles flow through the screen perforations when the materials are fed onto the screen, while bigger particles are held on the screen surface.

How do I keep a Multi Deck Vibrating Screen in good condition?

Cleaning the screen surfaces, examining and tightening bolts and fasteners, lubricating bearings, and evaluating overall performance are all examples of routine maintenance practices for a Multi Deck Vibrating Screen. It is best to follow the manufacturer's instructions and perform routine checks to maintain optimal performance and extend the screen's lifespan.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese