Call Us Now :-08071932023

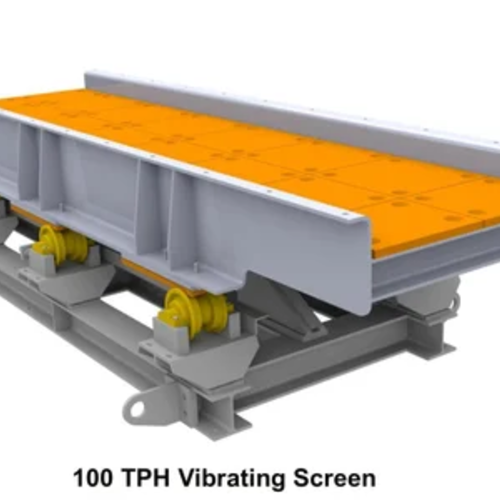

Linear Vibrating Screens

2400000 INR/Unit

Product Details:

- Type Vibrating Screen

- Material Mild Steel

- Condition New

- Product Type Vibrating Screen

- Power Mode Electric

- Application Industrial

- Click to view more

X

Linear Vibrating Screens Price And Quantity

- 2400000 INR/Unit

- 1 Unit

Linear Vibrating Screens Product Specifications

- Mild Steel

- Vibrating Screen

- Vibrating Screen

- Electric

- Industrial

- New

Linear Vibrating Screens Trade Information

- Letter of Credit (L/C), Cash in Advance (CID), Cheque, Cash Advance (CA)

- 7-8 Months

- South America, Western Europe, Australia, North America, Eastern Europe, Middle East, Central America, Africa, Asia

- All India

Product Description

We have established ourselves as a prominent manufacturer of vibrating screens in the country. Our range primarily includes two types: circular motion vibrating screens and linear motion vibrating screens. These screens find extensive usage in industries such as ceramics, food, chemicals, and coarse to medium-fine applications.

Circular Motion Vibrating Screens:

- Two-bearing free-floating design

- Efficient screening of moderately free-flowing materials

- Rapid stratification at the feed end for precise sizing

- Minimizes processing time

Linear Motion Vibrating Screens:

- Ideal for screening bulk material

- Sturdy screen construction available in welded or bolted design

- Driven by one or multiple exciters or unbalanced motors

- Compatible with various screen mats

- Suitable for installation in confined spaces

Sizes Available of Linear Vibrating Screens:

- Imbalanced Weight (Geared Type) Construction: Widths: 1000 mm to 3800 mm Lengths: 2500 mm to 10000 mm

- Imbalanced Motor Construction: Widths: 400 mm to 1250 mm Lengths: 1250 mm to 3000 mm

- Process Application: Separation/Classification/Sizing/Draining

- Industrial Application: Iron Ore Beatification Plants/Iron Ore Washing Plants/Sand Washing Plant.

Linear Vibrating Screens Benefits

- High screening efficiency for precise material separation and classification

- The ability to work with a diverse range of materials and applications.

- Low power usage and simple construction

- Simple to use and maintain

- Screening of both wet and dry materials that is effective

- Reduced downtime and increased productivity

- For customized screening, the amplitude and frequency may be adjusted.

- dependable operation with less noise and vibration

Download Brochure

Linear Vibrating Screens FAQs

A linear vibrating screen works on what principle?

A linear vibrating screen works by vibrating the screen box, which allows materials to travel over the screen surface. An electric motor with an imbalanced weight or a vibrating component causes the vibration. Smaller particles flow through the perforations in the screen, whereas bigger particles remain on the screen.

What are the primary parts of a linear vibrating screen?

The screen box, which contains the screen mesh, the vibration exciter, which creates the vibrating motion, the damping system, which decreases vibrations, and the support base, which provides stability and support for the screen are the key components of a linear vibrating screen

What are the benefits of employing a linear vibrating screen?

Linear vibrating screens provide a number of advantages. They provide great screening efficiency, guaranteeing precise material separation and categorization. They are appropriate for a wide range of applications and can work with a variety of materials.

What materials can a linear vibrating screen handle?

Minerals, metals, coal, aggregates, chemicals, and other materials can be processed using a linear vibrating screen. It is widely utilized in mining, quarrying, building, recycling, and chemical processing

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese