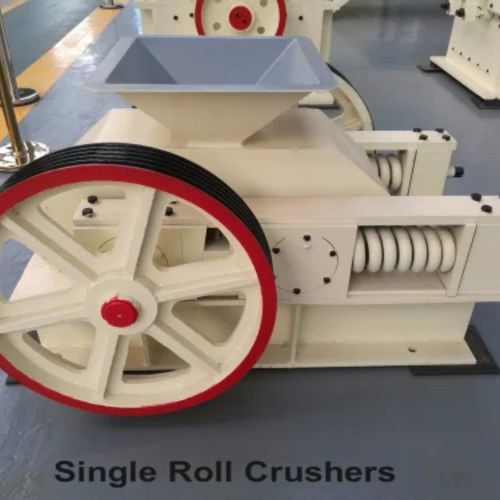

Single Roll Crusher

Product Details:

- Product Type Roll Crusher

- General Use Industrial

- Automatic Yes

- Feature High Performance High Efficiency

- Click to view more

Single Roll Crusher Price And Quantity

- 1 Unit

Single Roll Crusher Product Specifications

- Yes

- Industrial

- Roll Crusher

- High Performance High Efficiency

Single Roll Crusher Trade Information

- Cash in Advance (CID) Letter of Credit (L/C) Cheque Cash Advance (CA)

- 7-8 Months

- Eastern Europe Western Europe Australia Central America Africa Middle East South America Asia North America

- All India

Product Description

Ecoman is a leading crusher manufacturing, offering, and distribution company known for its efficient and customized single roll crushers designed to meet the unique requirements of various industrial applications. Our product range includes high-quality single roll crushers and two types of double roll crushers: double toothed roll crushers and smooth double roll crushers, along with sinter crushers.

Single roll crushers are small and durable equipment that are used for primary crushing in a variety of industries. They are made up of a revolving roller with a big tooth and a crushing plate that may be adjusted. The material to be crushed is fed into the crusher's top and crushed initially by the teeth on the spinning roller. It is then reduced in size even further when it travels through the adjustable crushing plate.

Single Roll Crusher Benefits

- Design is both compact and sturdy.

- Versatile and capable of working with a variety of materials.

- Primary crushing solution that is effective.

- Adjustable crushing plate allows for variable output size.

- Durability is ensured by the sturdy steel foundation and frame structure.

Type are manufactured in two types

- E-11 DOS-Heavy Duty.

- E-1100L-Light Duty.

Technical Data Single Roll Crusher (Light - Duty) Type E 1100 L

|

Size |

A |

I B I |

C |

D |

E |

F |

H |

I |

K |

L |

M |

weight |

|

1150/40 |

500 |

400 |

300 |

400 |

670 |

250 |

700 |

300 |

400 |

960 |

1400 |

1750 |

|

1150/80 |

500 |

800 |

300 |

400 |

670 |

250 |

700 |

300 |

400 |

1360 |

1800 |

2500 |

|

1150/120 |

500 |

1200 |

300 |

400 |

670 |

250 |

700 |

300 |

400 |

1760 |

2200 |

3300 |

|

1165/40 |

650 |

400 |

380 |

475 |

775 |

250 |

850 |

375 |

475 |

970 |

1410 |

2250 |

|

1165/80 |

650 |

800 |

380 |

475 |

775 |

250 |

850 |

375 |

475 |

1370 |

1810 |

3600 |

|

1165/120 |

650 |

1200 |

380 |

475 |

775 |

250 |

850 |

375 |

475 |

1770 |

2210 |

5000 |

|

1180/80 |

800 |

800 |

450 |

550 |

850 |

250 |

1000 |

450 |

550 |

1380 |

1850 |

5000 |

|

1165/120 |

800 |

1200 |

450 |

550 |

850 |

250 |

1000 |

450 |

550 |

1780 |

2250 |

7200 |

|

1180/160 |

800 |

1600 |

450 |

550 |

850 |

250 |

1000 |

450 |

550 |

2180 |

2650 |

10000 |

|

1110/80 |

1000 |

800 |

550 |

650 |

950 |

250 |

1200 |

550 |

650 |

1390 |

1860 |

8300 |

|

1110/120 |

1000 |

1200 |

550 |

650 |

950 |

250 |

1200 |

550 |

650 |

1790 |

2260 |

10200 |

|

1110/160 |

1000 |

1600 |

550 |

650 |

950 |

250 |

1200 |

550 |

650 |

2190 |

2260 |

12000 |

|

1110/200 |

1000 |

2000 |

550 |

650 |

950 |

250 |

1200 |

550 |

650 |

2590 |

3060 |

13800 |

|

1112/120 |

1200 |

1200 |

650 |

750 |

1050 |

250 |

1400 |

650 |

750 |

1800 |

2270 |

12600 |

|

1112/160 |

1200 |

1600 |

650 |

750 |

1050 |

250 |

1400 |

650 |

750 |

2200 |

2670 |

15400 |

|

1112/200 |

1200 |

2000 |

650 |

750 |

1050 |

250 |

1400 |

650 |

750 |

2600 |

3140 |

17800 |

|

1112/240 |

1200 |

2400 |

650 |

750 |

1050 |

250 |

1400 |

650 |

750 |

3000 |

3540 |

20400 |

Dimensions & Ratings Indicative Not Binding.

Technical Data Single Roll Crusher (Heavy- Duty) Type E 1100 S

|

Size |

A |

I B I |

C |

D |

E |

F |

H |

I |

K |

L |

M |

Weight |

|

1110/80 |

1060 |

800 |

125 |

1480 |

1030 |

490 |

3000 |

1550 |

1950 |

1165 |

2400 |

14500 |

|

1110/120 |

1060 |

1200 |

1650 |

1480 |

1030 |

490 |

3000 |

1550 |

1950 |

1165 |

2875 |

16900 |

|

1110/150 |

1060 |

1500 |

1950 |

1480 |

1030 |

490 |

3000 |

1550 |

1950 |

1165 |

3250 |

18800 |

|

1110/180 |

1060 |

1800 |

2250 |

1480 |

1030 |

490 |

3000 |

1550 |

1950 |

1165 |

3625 |

20400 |

|

1112/120 |

1200 |

1200 |

1700 |

1610 |

1045 |

485 |

3140 |

1850 |

2150 |

1250 |

3000 |

20000 |

|

1112/150 |

1200 |

1500 |

2000 |

1610 |

1045 |

485 |

3140 |

1850 |

2150 |

1250 |

3375 |

22600 |

|

1112/180 |

1200 |

1800 |

2300 |

1610 |

1045 |

485 |

3140 |

1850 |

2150 |

1250 |

3750 |

25500 |

|

1112/220 |

1200 |

2200 |

2700 |

1610 |

1045 |

485 |

3140 |

1850 |

2150 |

1250 |

4300 |

28500 |

|

1116/150 |

1600 |

1500 |

2100 |

1750 |

1060 |

570 |

3380 |

2150 |

2400 |

1500 |

3750 |

33000 |

|

1116/180 |

1600 |

1800 |

2400 |

1750 |

1060 |

570 |

3380 |

2150 |

2400 |

1500 |

4125 |

38000 |

|

1116/210 |

1600 |

2100 |

2700 |

1750 |

1060 |

570 |

3380 |

2150 |

2400 |

1500 |

4500 |

42800 |

|

1116/240 |

1600 |

2400 |

3000 |

1750 |

1060 |

570 |

3380 |

2150 |

2400 |

1500 |

4875 |

47500 |

|

1116/280 |

1600 |

2800 |

3400 |

1750 |

1060 |

570 |

3380 |

2150 |

2400 |

1500 |

5300 |

53000 |

Dimensions & ratings indicative Not Binding.

Specifications of the single roll crusher

- Sizes available : Diameter 500 mm x Width 400 mm to Diameter 1600 mm to Width 2800 mm

- Maximum Feed Size : 2000 mm

- Capacity (TPH) : 2000

Single Roll Crusher FAQs

How simple is it to keep single roll crushers running?

Single roll crushers are made to be simple to maintain. They usually have changeable, reversible, and renewable crushing plates, which make maintenance easier and save downtime. Furthermore, some versions may have automated oil lubrication systems, which simplify maintenance and ensure smooth functioning.

Are single roll crushers capable of handling big feed sizes?

Single roll crushers are typically built to handle lower feed sizes than other types of crushers. The maximum feed size capacity will be determined by the model and its design.

What type of power source is required to run single roll crushers?

Electric motors are commonly used to power single roll crushers. The particular power needs will be determined by the crusher's size and capacity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese