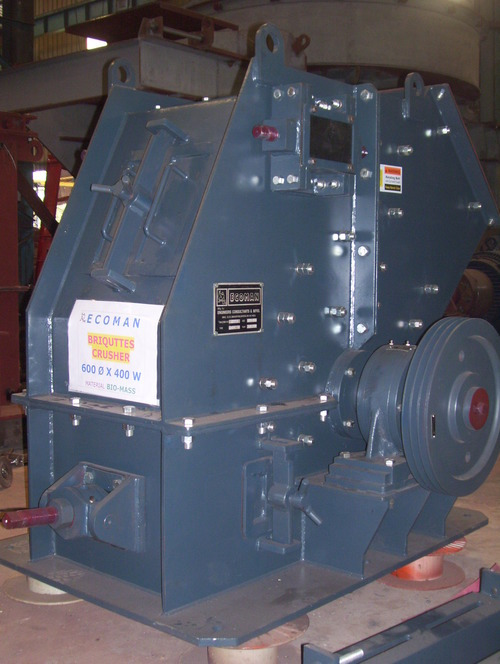

Jaw Crusher

Product Details:

- Product Type Crusher

- Usage Industrial

- Equipment Type Jaw Crusher

- Condition New

- Material Mild Steel

- Power Source Electric

- Power(W) 380 Volt (v)

- Click to view more

Jaw Crusher Price And Quantity

- 1475000 INR/Unit

- 1 Unit

Jaw Crusher Product Specifications

- 380 Volt (v)

- Electric

- New

- Mild Steel

- Crusher

- Jaw Crusher

- Industrial

Jaw Crusher Trade Information

- Cash in Advance (CID) Cheque Cash Advance (CA) Letter of Credit (L/C)

- 7-8 Months

- Asia Australia North America South America Eastern Europe Western Europe Middle East Africa Central America

- All India

Product Description

The inside Story

- Ensured crushing without rubbing with hinge pin on the crushing chamber center line, large bearings and integral lubrication.

- Wide entry throat ensures easy feeding to crushing chamber.

- Fabricated swing jaw is balanced to avoid power losses through lifting on crushing stroke.

- A light small diameter flywheel is all that is necessary with the low inertia of the mechanism.

- Operating mechanism is totally enclosed for maximum life and minimum maintenance.

- All adjustment are carried out on the fixed jaw to avoid disturbing the crushing geometry.

- List of dimensions gives approximate sizes only and serve as a guide only for plant arrangement. They should not be accepted as the actual dimensions.

- We reserve the right to make any alterations, or Modifications which we consider an improvement.

- For actual installation work ask for GA drg.

In addition, the Jaw crushers have wide utility in several sectors. These are demanded in the industry of mining and quarrying for crushing abrasive and hard materials such as basalt, granite, gravel, and ore. The machines can process the large rocks into smaller parts. In this way, the crushing machines can make the materials into several manageable sizes. The said machines have crucial role in recycling processes as they can process the recyclable materials such as concrete, demolition waste and asphalt. Supplied machines allow for simple transportation, handling and advanced processing of recycled materials.

Jaw Crushers Benefits

Capacity Power Speed:

|

Ecoman Jaw Crusher Size |

Max Feed Size mm |

Motor HP |

Motor Speed |

Crusher Speed RPM |

INS 3/4 |

1" |

1.5" |

2" |

2.5" |

3" |

3.5" |

4" |

5" |

6" |

7" |

8" |

9" |

10" |

11" |

Max. feed |

|

12x7 |

125 |

15 |

1440 |

365-400 |

8 |

9 |

10 |

15 |

18 |

|

|

|

|

|

|

|

|

|

|

|

|

16x6 |

115 |

25 |

1440 |

365-400 |

13 |

17 |

20 |

25 |

30 |

40 |

|

|

|

|

|

|

|

|

|

|

|

16x9 |

175 |

25 |

1440 |

365-400 |

|

15 |

17 |

20 |

25 |

30 |

|

|

|

|

|

|

|

|

|

|

|

20x10 |

200 |

30 |

1440 |

365-400 |

|

15 |

17 |

18 |

24 |

34 |

|

|

|

|

|

|

|

|

|

|

|

24x12 |

250 |

30 |

1440 |

365-400 |

|

|

|

30 |

40 |

45 |

50 |

|

|

|

|

|

|

|

|

|

|

30x6 |

115 |

30 |

1440 |

400-450 |

18 |

22 |

27 |

31 |

36 |

|

|

|

|

|

|

|

|

|

|

|

|

30x15 |

300 |

40 |

1440 |

350-380 |

|

|

|

|

45 |

50 |

65 |

75 |

85 |

|

|

|

|

|

|

|

|

30x20 |

400 |

40 |

1440 |

350-375 |

|

|

|

|

44 |

50 |

65 |

75 |

85 |

115 |

|

|

|

|

|

|

|

36x6 |

115 |

40 |

1440 |

350-400 |

27 |

31 |

36 |

40 |

45 |

|

|

|

|

|

|

|

|

|

|

|

|

36x24 |

500 |

75 |

1440 |

325-360 |

|

|

|

|

|

|

100 |

115 |

130 |

155 |

|

|

|

|

|

|

|

42x6 |

115 |

50 |

1440 |

350-400 |

36 |

40 |

45 |

49 |

54 |

|

|

|

|

|

|

|

|

|

|

|

|

42x24 |

500 |

120 |

1440 |

300-350 |

|

|

|

|

|

|

|

|

140 |

160 |

180 |

200 |

210 |

230 |

240 |

|

|

42x30 |

650 |

150 |

1440 |

300-320 |

|

|

|

|

|

|

|

|

140 |

160 |

180 |

200 |

210 |

230 |

240 |

|

|

48x10 |

200 |

75 |

1440 |

300-375 |

|

48 |

52 |

56 |

64 |

80 |

88 |

92 |

96 |

|

|

|

|

|

|

|

|

60x48 |

1000 |

200 |

1440 |

225-275 |

|

|

|

|

|

|

|

|

|

|

350 |

405 |

460 |

510 |

520 |

610 |

Jaw Crushers FAQs

What are the main components of a jaw crusher?

The key constituents of the jaw crusher include the following:

- Fixed jaw is an important part of crusher which has been made for housing the crushing compartment.

- Movable jaw has been made to apply the force to the rock.

- Jaw plates are plates, resistant to wear, which can cover the crushing surfaces of the jaws.

- Eccentric shaft is made to convey the motor's rotating motion.

- Toggle plate is also incorporated as a safety device that helps in conveying the crushing power. It also ensures the protection of crusher from damage caused by overloading.

What are the limitations of a jaw crusher?

What is the working principle of jaw crusher?

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese